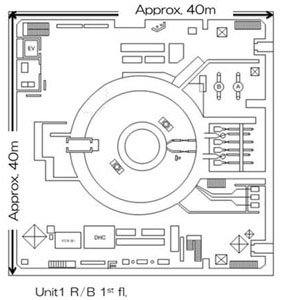

Example of method 1 "Retrieving fuel debris from the top (fixed transporting equipment)”

Index > Considerations - 3. Seismic safety|Example of method 1 "Retrieving fuel debris from the top (fixed transporting equipment)”

ⅱ) Considerations - 3. Seismic safety

Issues to be noted for the proposing method in terms of safety are explained below.

- Consideration shall be made for seismic safety and spesific study shall be performed in C/S

Issues requiring special attention 3. Seismic safety

(1) Prior preparation

- Seismic assessment when creating opening on the building for investigation and fuel debris retrieval

(2) Install barrier

- Seismic assessment of barrier equipment

- Seismic assessment of building when installing barrier on the operation floor

(3) Remove shield plug

(4) Remove PCV/RPV upper head

(5) Install equipment and access

- Seismic assessment of equipment for fuel debris retrieval

- Seismic assessment for the building when installing equipment on the operation floor (including shielding equipment)

(6) Dismantle and remove internal structures

- Seismic assessment of equipment for retrieving fuel debris

- Structural stability of internal structures during dismantling of internal structures

(7) Retrieve fuel debris

(8) Collect fuel debris and Transfer canisters

(9) Clean-up equipment

| Plant information |

|---|

| Assumptions and prerequisites |

|

|---|